All dirt bike wheels usually have a rim lock but not everyone knows what they are and how they work. I remember the first time I saw what looked like another inner tube valve stem poking through the wheel rim and I was a bit mythed.

For those of you in a rush here is the compact answer.

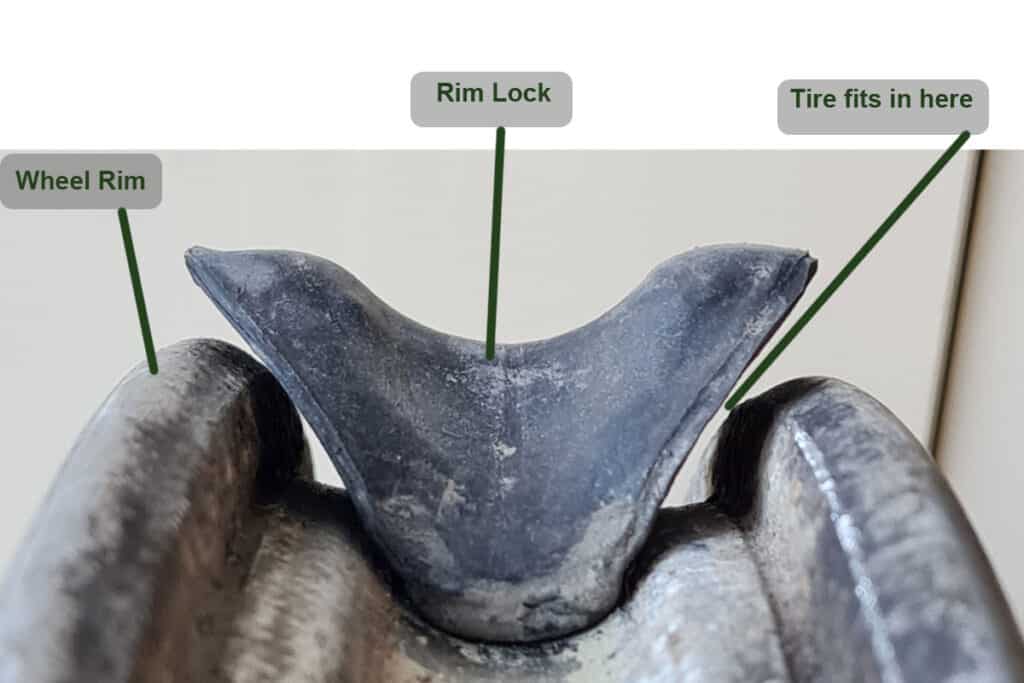

Tightening the nut of the rim lock, located between the spokes of the wheel, clamps the tyre bead from the inside, against the rim of the wheel. This prevents the tire from being able to spin freely on the rim and will also keep the tire in place in the event of a flat.

If the tire is able to spin on the rim then you stand a high chance of the inner tube also rotating and tearing out the valve stem in the process. This would result in an instant flat.

As I mentioned above, if you get a flat, assuming it’s not down to the fact you just ripped your valve stem out, then the wheel will remain clamped in position with the aid of the rim lock.

This gives you a fighting chance of being able to repair the tube even if its just a temporary solution until you get home. People commonly use products like tube slime for this which can be used both prior to a puncture or afterwards. You just add the slime into the inner tube and it finds and seals the hole. A good inexpensive solution that could get you out of a jam. Your other option could be to carry a spare inner tube.

The rim lock is made from a mix of materials but is mainly made using a cast metal block which is coated in rubber. This sits snugly seated on the rim with a threaded bolt sticking through a hole so a nut and washer can be used to clamp it tight.

How To Install A Dirt Bike Rim Lock

Installing the rim lock is an easy process assuming you already had one in the first place. If you didn’t but you are adding one then you will need to drill a new hole to accomodate the rim lock in the rim.

Choose a place for your new rim lock to be positioned and drill the correct size hole so the threaded bolt will fit with the smallest amount of space around it as you can get.

It’s commonly positioned at the opposite side of the rim to the stem valve. Its also worth noting that you do not want to make a new hole where the rim weld is. This is the factory weld from where the rim was made and welded into a circle.

When selecting the point for drilling the hole make sure you have enough space between the spoke nipples, as not all wheels have evenly spaced nipples, some have them spaced in pairs which means you have a bigger gap every other spoke.

So now you have either made a new hole or already have an exisiting hole you simply take off the washer and nut and insert the rim lock so it is seated on the rim.

You will then place your rim tape over the rim and which will cover the spoke nipples as well as running over the rim lock. Be sure to line up the hole in the band with the hole for your stem valve.

Tip: Make sure the lock rim is squarley seated so it doesnt end up catching the inner tube and causing a tear. Do this by loosening the nut a few turns and pushing the thread a couple times back into the tube allowing it to find its own position. Do this before the tube is fully inflated.

Then you go about fitting the rest of your wheel as normal. So first side of the tire followed by the inner tube, then the remaining otherside of the tire.

Dirt Bike Rim Lock Sizes

Rim locks do come in different sizes because wheel rims do. You need to make sure you get the appropriate sized rim lock size for your rim, otherwise you risk damage to the tube and the tire.

The esiest way to find out the size you need is to consult your bikes manual, but failing that you can check online at a parts website for the part number then Google that to get the size if they don’t state it.

Websites like Rocky Mountain will ask you for the model of bike you have and then tell you the right size rim lock. Thats cool as long as you have factory spec rims because they wont know any different.

Do I Need Rim Locks On My Dirt Bike?

In my opinion yes you do.

Rim locks are needed to ensure the tire doesn’t spin seperately to the rim which can happen on both acceleration and hard braking. The result of which could lead to tearing out a valve stem in an instant.

Considering most dirt bikes will have rim locks anyway I don’t see a reason for taking them out. The questions of ‘do you need them’ would therefore imply your bike doesn’t have them in the first place and if that’s the case you will have to decide.

If you have a dirt bike that you just potter about on then maybe you don’t need them but in most cases it is better off with them than without.

If you are installing new rim locks then it would be a good idea to get your wheel balanced. This is because you have added weight on the rim and at higher speeds you will notice a vibration as the centrifugal force picks up and wants to push the weight out more and more the faster you go.

When you balance a wheel you add weights to counteract any offset weight and make the wheel ‘balanced’.

Rim Locks With Mousse Wheel and Tubless Systems

If you are not running a standard tubed tire setup, that is your wheel rim with an inner tube and then your bike tire, then you either have a tire mousse or a tubeless system installed.

The mousse is a foam tube that replaces the inner tube and the foam alone acts as the cushioning so no air is required. The main benefit is the you can’t puncture a mousse.

If you are running a mousse then you will still need a rim lock to secure the tire to the rim.

The tubeless systems I have seen use two valves and one of them doubles up as a rim lock so in this case you will not require a seperate one. If you are running a tubeless tire system then you will know this already. If you were thinking about the switch…well now you know.